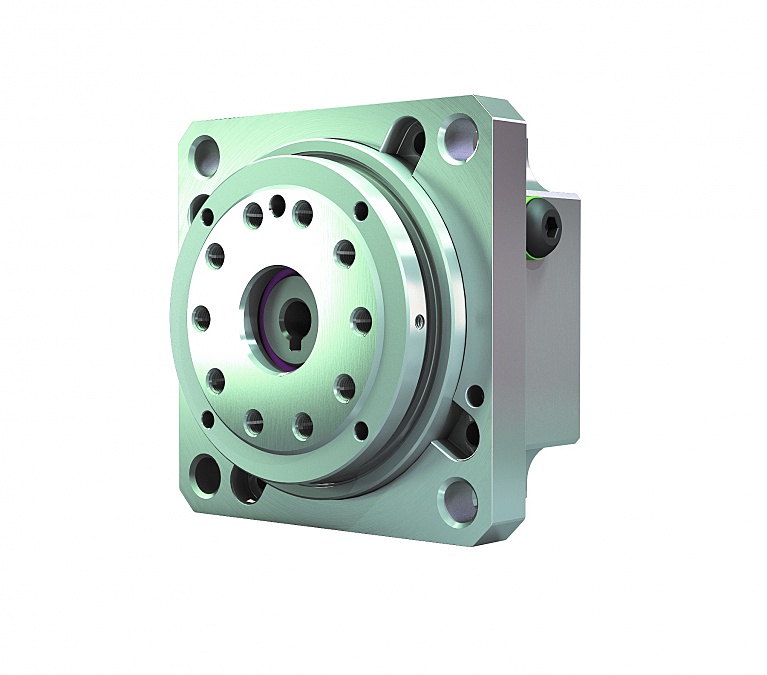

M - Gamme TwinSpin ultra-compact

La série M concerne des réducteurs de haute précision de taille très compacte

Le premier modèle de la série est la taille TS 50 et il est prévu de proposer des réducteurs TwinSpin encore plus petits qui compléteront la série M.

La série M offre toutes les qualités des grands engrenages Spinea. La série M comprend un engrenage complètement étanche et graissé pour une durée de vie exceptionelle. Cette conception des réducteurs permet le montage de la charge directement sur la bride de sortie ou sur le carter sans nécessiter de roulements supplémentaires.

Avantages

- Petites dimensions et design compact

- Série entièrement étanche

- Possibilités d'installation simples

- Réducteur à jeu nul

- Très faible masse

- Très haute densité de puissance

- Roulement de sortie à billes à gorge profonde à très faible frottement

- Haute performance du réducteur

- Haute précision

- Haute rigidité à la torsion

- Haute linéarité des caractéristiques de torsion

- Très faible inertie d'entrée

- Très bonnes vibrations

- Très faible frottement et haut rendement